Animal Feed Plant - Step-by-Step Operating Process

Step 1: Raw Material Intake

The process begins with the intake of raw materials such as maize, wheat, barley, rice bran, oil cakes, pulses, minerals, and feed additives used in animal feed production.

- Feed Hopper Machine: Raw materials are loaded into the hopper to ensure controlled storage and smooth material flow.

- Belt Conveyor: Transfers bulk raw materials from storage areas to the processing section efficiently.

- Bucket Elevator: Lifts raw ingredients vertically to the grinding section, optimizing floor space and maintaining dust-free handling.

Step 2: Grinding (Mash Preparation)

Grinding ensures proper digestion and nutrient absorption for animals.

- Vibro Feeder Machine: Provides a uniform and regulated feed flow into the grinder, preventing overloading and uneven grinding.

- Hammer Mill / Feed Grinder Machine: Grinds raw materials into a medium-fine mash, adjustable based on the type of animals (goat, sheep, pig, or other livestock).

Step 3: Mixing & Nutrient Dosing

This stage ensures consistent nutrition in every batch of feed.

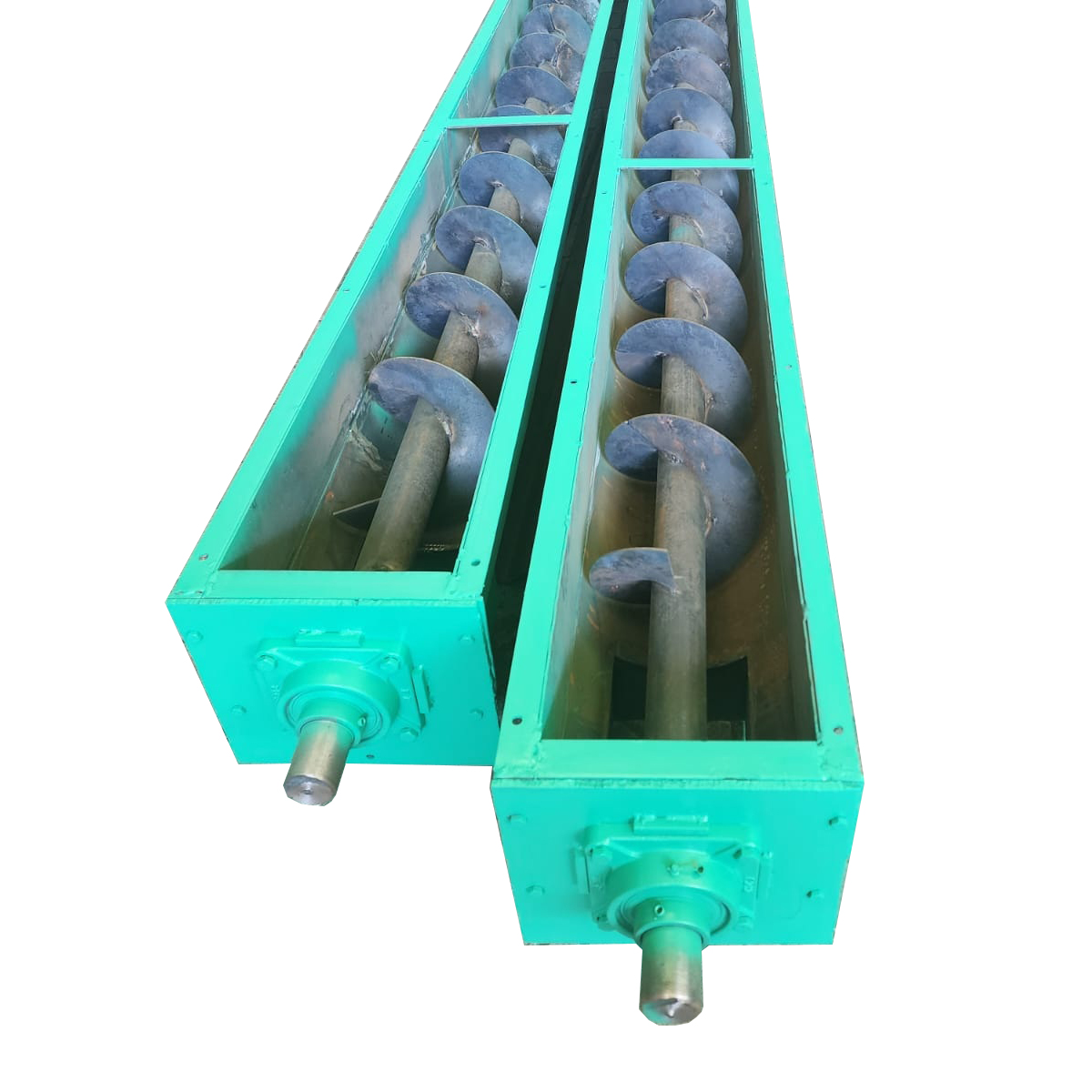

- Screw Conveyor: Transfers the ground mash from the hammer mill to the mixer in an enclosed system, reducing dust and material loss.

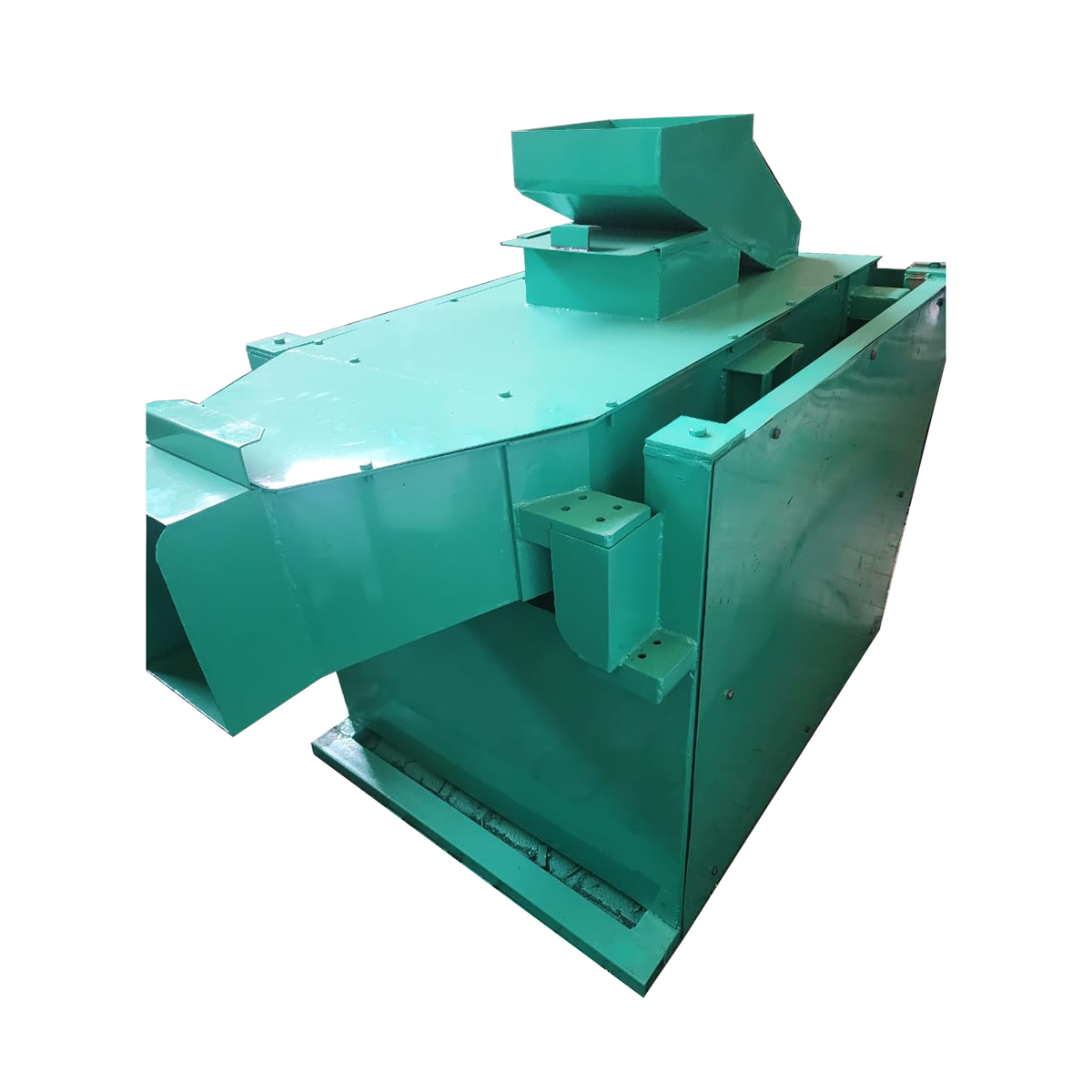

- Feed Mixture Machine: Vitamins, minerals, supplements, and micro-ingredients are added and thoroughly mixed to produce a homogeneous animal feed blend.

Step 4: Pelleting Process

The mixed feed mash is converted into solid animal feed pellets.

- Feed Pellet Mill: Compresses the mash through a precision-engineered die to form uniform animal feed pellets. Pellet size and density can be adjusted according to animal type and feeding requirements.

Step 5: Cooling Process

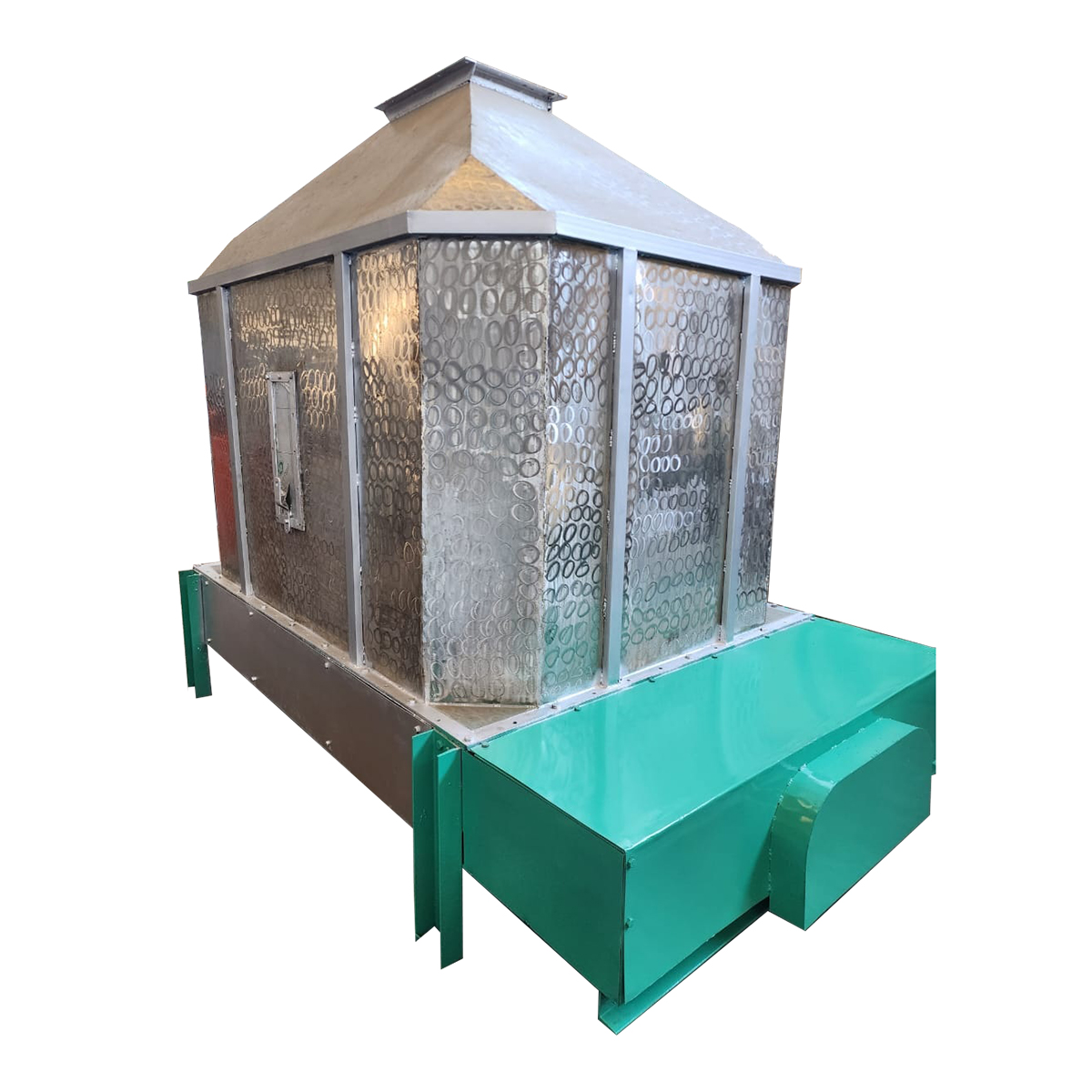

Freshly produced pellets are hot and soft and must be stabilized.

- Cattle Feed CF Cooler: Uses ambient air to reduce pellet temperature and moisture, improving pellet hardness, shelf life, and resistance to breakage.

Step 6: Final Conveying & Packing

The finished animal feed pellets are transported for storage or packing.

- Chain Conveyor: Gently conveys cooled pellets to storage bins or packing units, minimizing pellet breakage and dust formation.

Final Output

- Uniform and nutritionally balanced animal feed

- Strong, durable pellets with minimal fines

- Improved feed efficiency and digestibility

- Suitable for various livestock applications