Cattle Feed Plant - Step-by-Step Operating Process

Step 1: Raw Material Intake

The process begins with the intake of raw materials such as maize, wheat, rice bran, oil cakes, and mineral additives used in cattle feed production.

- Feed Hopper Machine: Raw materials are loaded into the hopper for temporary storage and controlled discharge.

- Belt Conveyor: Transfers bulk raw materials from the storage area to the processing line efficiently.

- Bucket Elevator: Lifts raw grains vertically to the grinding section, optimizing floor space and ensuring smooth material flow.

Step 2: Grinding (Mash Preparation)

Proper grinding improves digestibility and pellet quality for cattle feed.

- Vibro Feeder Machine: Ensures a consistent and regulated flow of material into the grinder, preventing motor overload and uneven grinding.

- Hammer Mill / Feed Grinder Machine: Grinds raw materials into a medium-coarse mash, ideal for cattle feed. Screen size is selected to maintain fiber structure while improving nutrient absorption.

Step 3: Mixing & Nutrient Dosing

This stage ensures uniform nutritional value in every pellet.

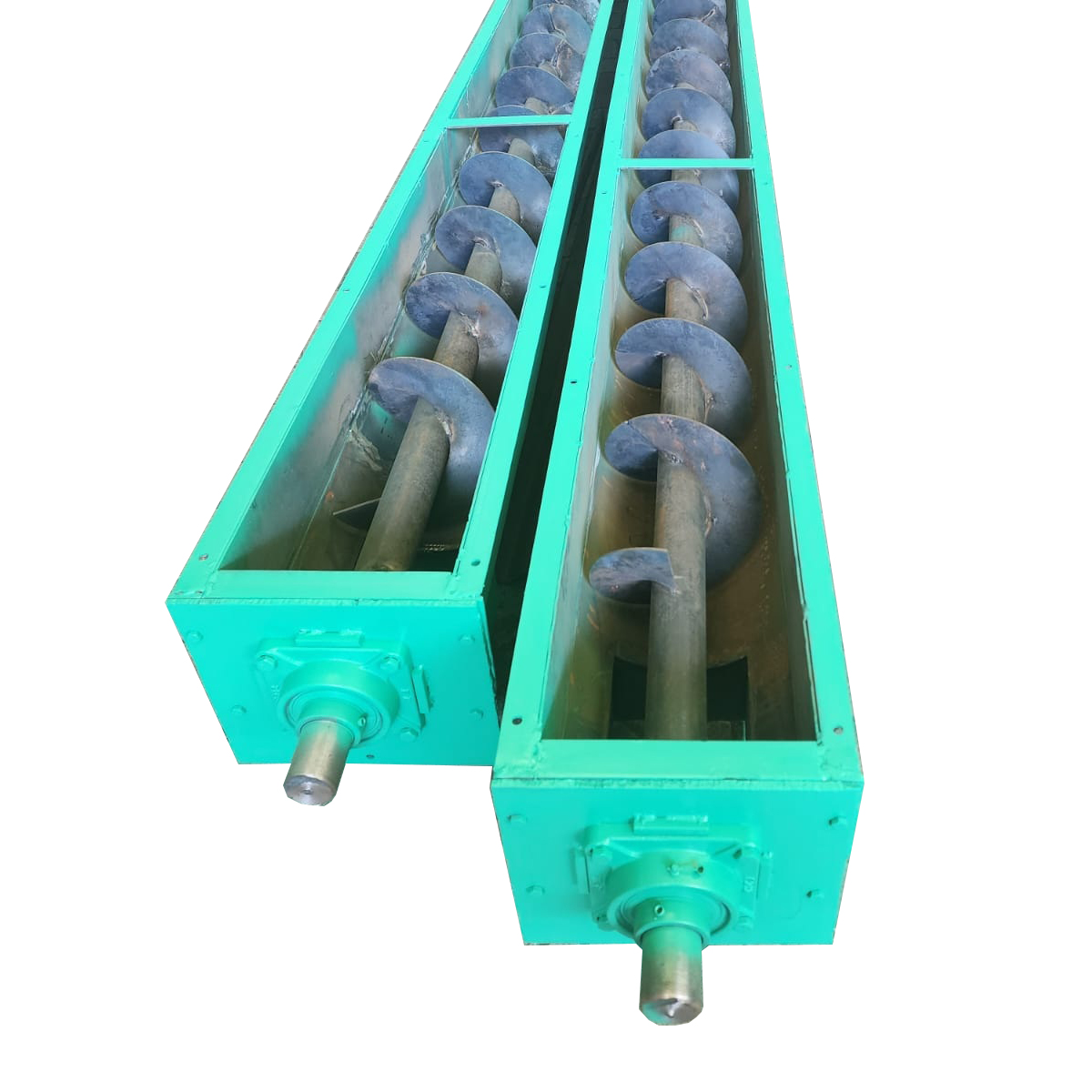

- Screw Conveyor: Transfers the ground mash from the hammer mill to the mixer in a closed system, minimizing dust and material loss.

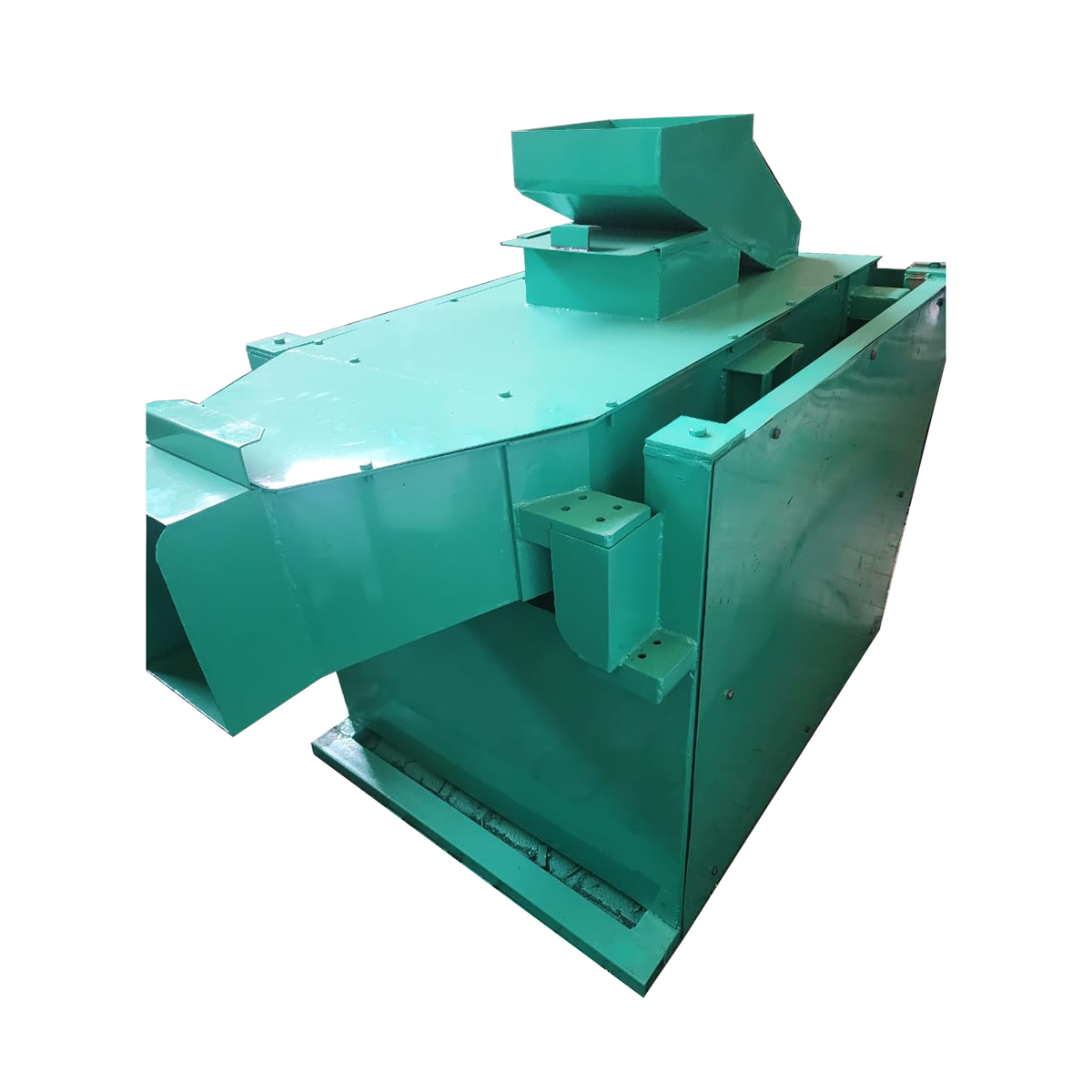

- Feed Mixture Machine: All feed ingredients, including minerals, vitamins, and supplements, are thoroughly mixed to produce a homogeneous cattle feed blend.

Step 4: Pelleting Process

The mixed mash is converted into solid cattle feed pellets.

- Feed Pellet Mill: The feed mash is compressed through a specially designed die to produce large-diameter, high-density cattle feed pellets that are easy to handle and store.

Step 5: Cooling Process

Fresh pellets are hot and soft and require stabilization.

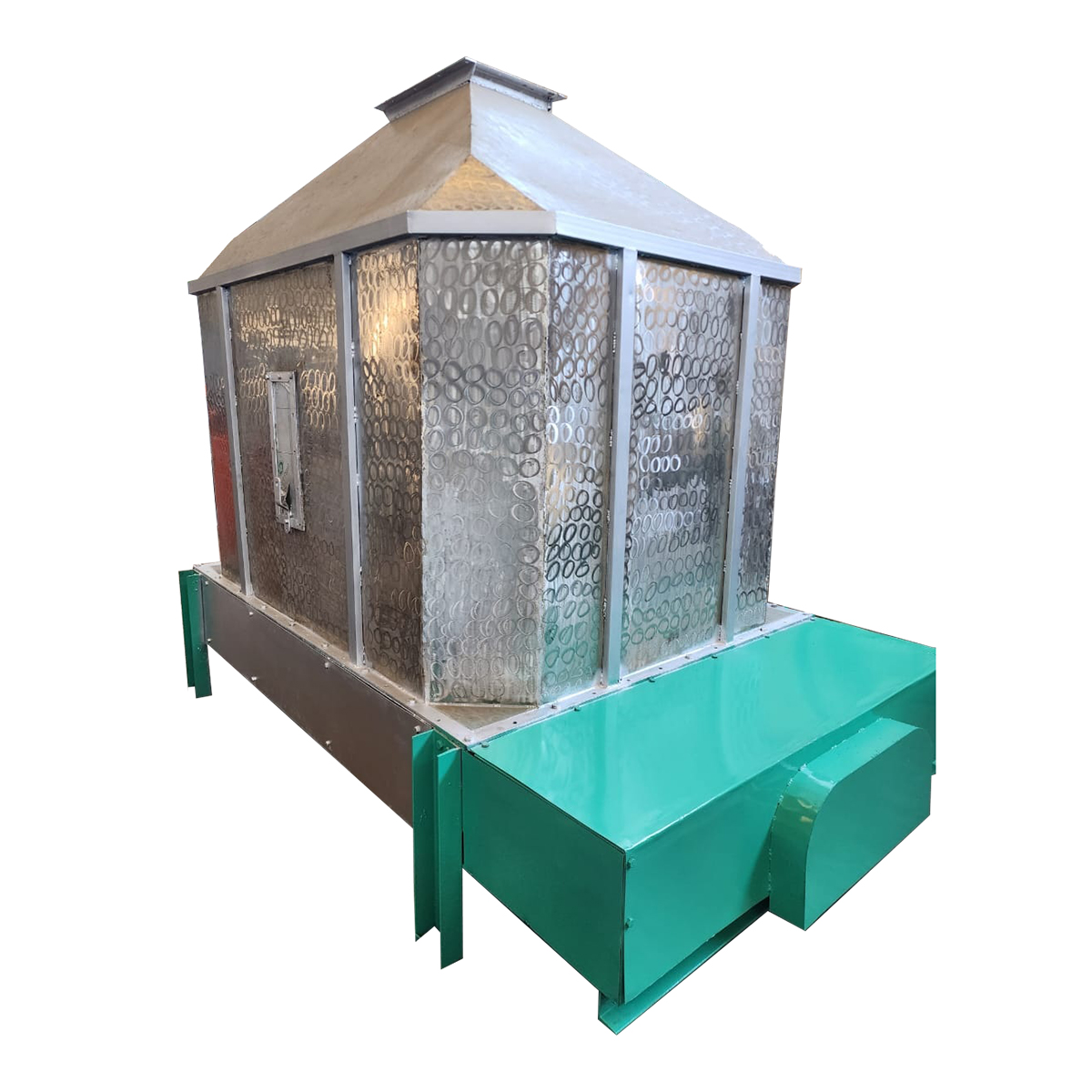

- Cattle Feed CF Cooler: Uses ambient air to reduce pellet temperature and moisture, increasing pellet hardness, durability, and shelf life while preventing fungal growth.

Step 6: Final Conveying & Packing

The finished cattle feed pellets are transferred for storage or packing.

- Chain Conveyor: Gently conveys cooled pellets to storage bins or packing units. Chain conveyors are preferred to reduce pellet breakage and dust formation.

Final Output

- Strong, uniform cattle feed pellets

- Balanced nutrition in every batch

- Improved shelf life and handling

- Low wastage and efficient production