Fish Feed Plant - Step-by-Step Operating Process

Step 1: Raw Material Intake

The process begins with the intake of raw materials such as fish meal, maize, soybean meal, wheat flour, rice bran, oils, and feed additives used in fish feed production.

- Feed Hopper Machine: Raw materials are loaded into the hopper for controlled storage and smooth feeding.

- Belt Conveyor: Transfers bulk raw materials from the storage area to the processing section efficiently.

- Bucket Elevator: Lifts raw materials vertically to the grinding section, saving floor space and ensuring dust-free handling.

Step 2: Fine Grinding (Micro Mash Preparation)

Fish feed requires ultra-fine grinding for better water stability and digestibility.

- Vibro Feeder Machine: Ensures a consistent and controlled feed flow into the grinder, preventing overloading and uneven grinding.

- Hammer Mill / Feed Grinder Machine: Grinds raw materials into a very fine mash using fine screens, suitable for fish feed pellet formation.

Step 3: Mixing & Nutrient Dosing

Precise formulation is critical in fish feed production.

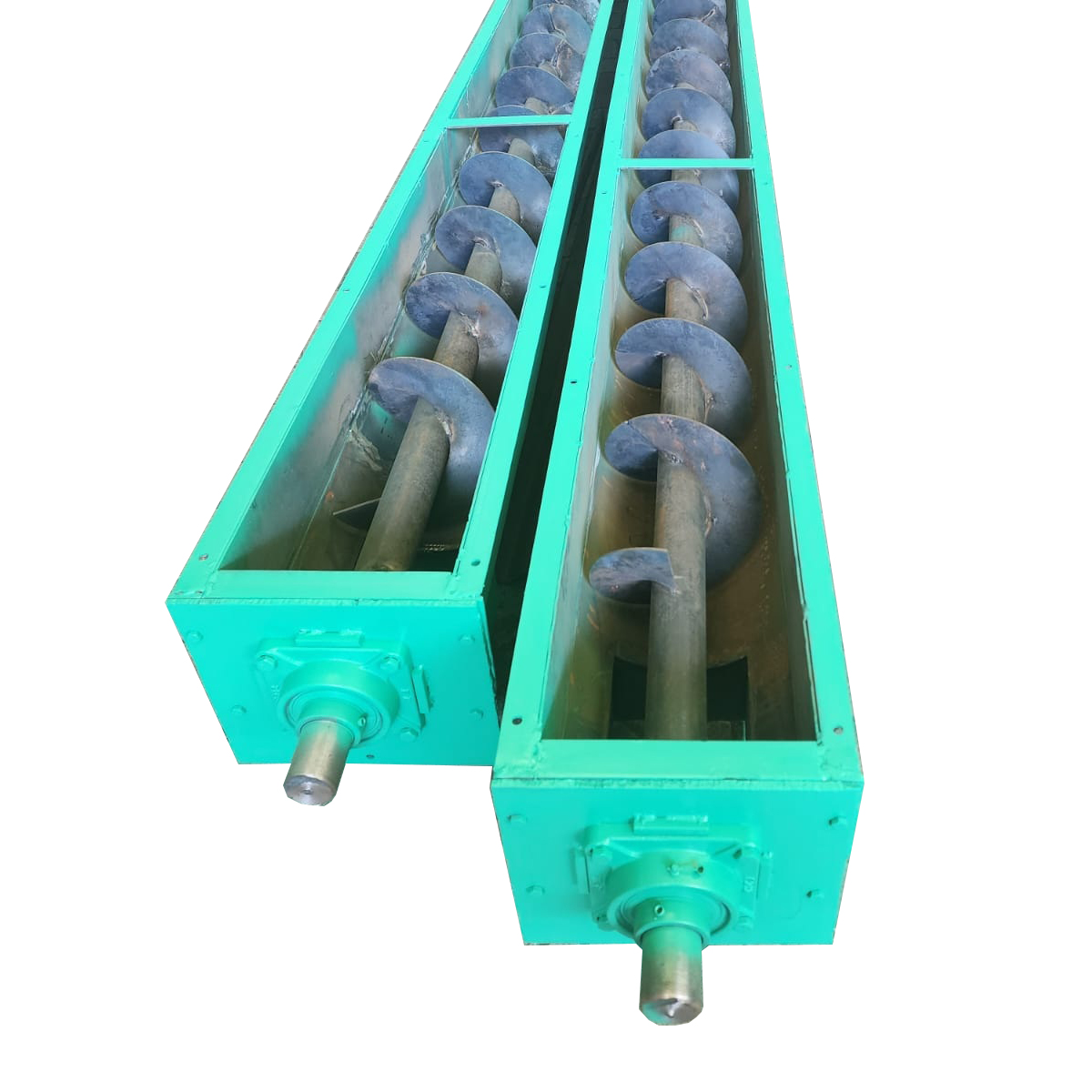

- Screw Conveyor: Transfers the finely ground mash to the mixer in a sealed system to minimize dust and contamination.

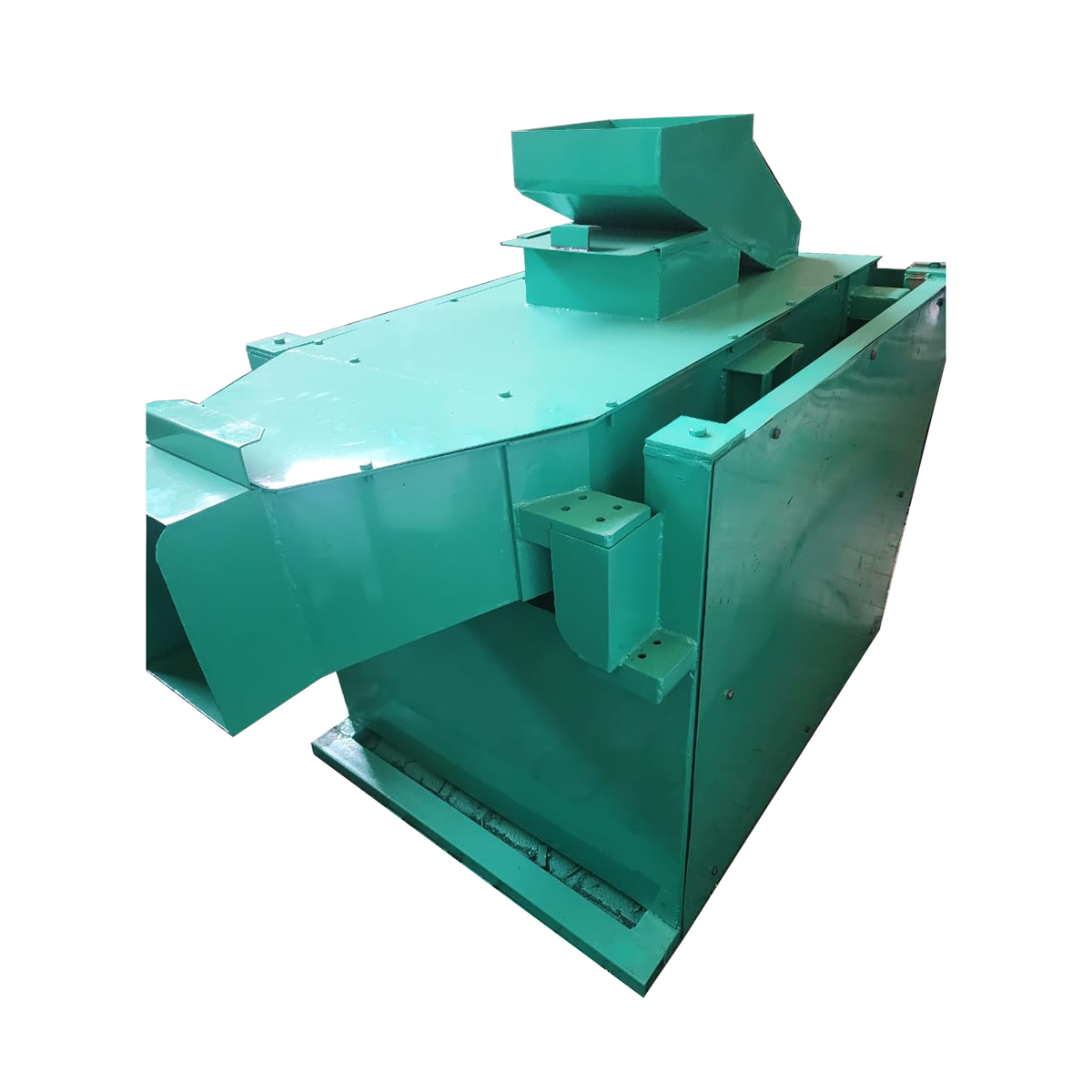

- Feed Mixture Machine: Oils, vitamins, minerals, and micro-ingredients are added and thoroughly mixed to ensure uniform nutrition in every pellet.

Step 4: Pelleting Process

The mixed mash is converted into fish feed pellets.

- Feed Pellet Mill: Compresses the mash through a specially designed die to produce small, dense fish feed pellets with good water stability and sinking or floating characteristics as required.

Step 5: Cooling & Stabilization

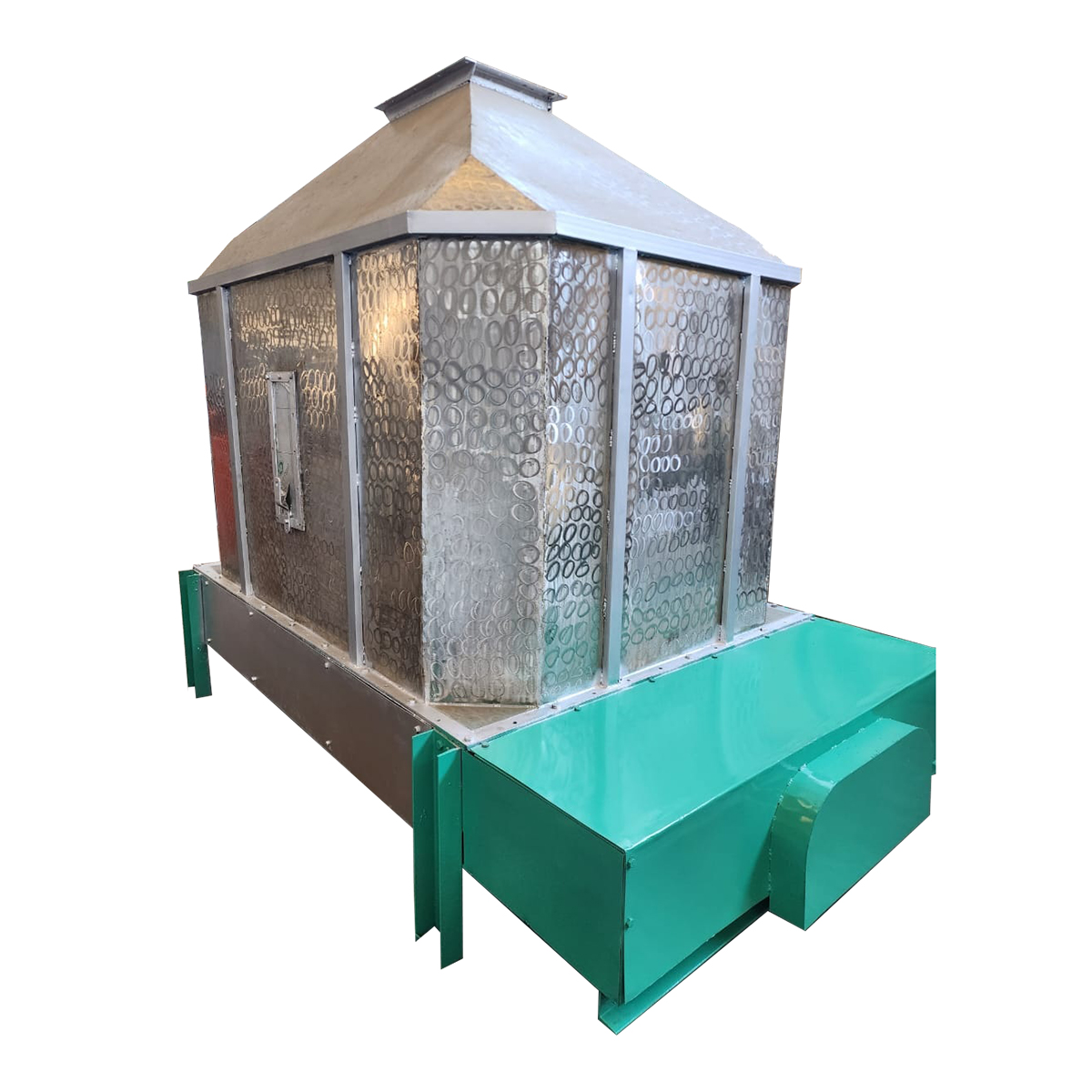

Fresh pellets are hot and soft and require cooling.

- Cattle Feed CF Cooler: Uses ambient air to reduce pellet temperature and moisture, improving pellet hardness, storage life, and water resistance.

Step 6: Crumbling (Optional - Fingerlings Feed)

For small fish and fingerlings, pellets are resized.

- Feed Crumbler Machine: Breaks pellets into uniform crumbles suitable for young fish.

Step 7: Final Conveying & Packing

Finished fish feed pellets or crumbles are transferred for storage or packing.

- Chain Conveyor: Gently conveys finished feed to storage silos or packing units, minimizing pellet breakage and dust.

Final Output

- Uniform, nutritionally balanced fish feed

- High water stability and digestibility

- Minimal fines and dust

- Suitable for fingerlings and adult fish