Poultry Feed Plant - Step-by-Step Operating Process

Step 1: Raw Material Intake

The process starts with the intake of raw ingredients such as maize, soybean meal, wheat, rice bran, oil cakes, and feed additives used in poultry feed production.

- Feed Hopper Machine: Raw materials are loaded into the hopper to ensure controlled and continuous feeding.

- Belt Conveyor: Transfers bulk raw materials from storage to the processing section efficiently.

- Bucket Elevator: Lifts raw materials vertically to the grinding section, saving floor space and maintaining smooth material flow.

Step 2: Grinding (Mash Preparation)

Poultry feed requires finer grinding for better digestion and feed conversion.

- Vibro Feeder Machine: Regulates the flow of material into the grinder, preventing overloading and ensuring uniform grinding.

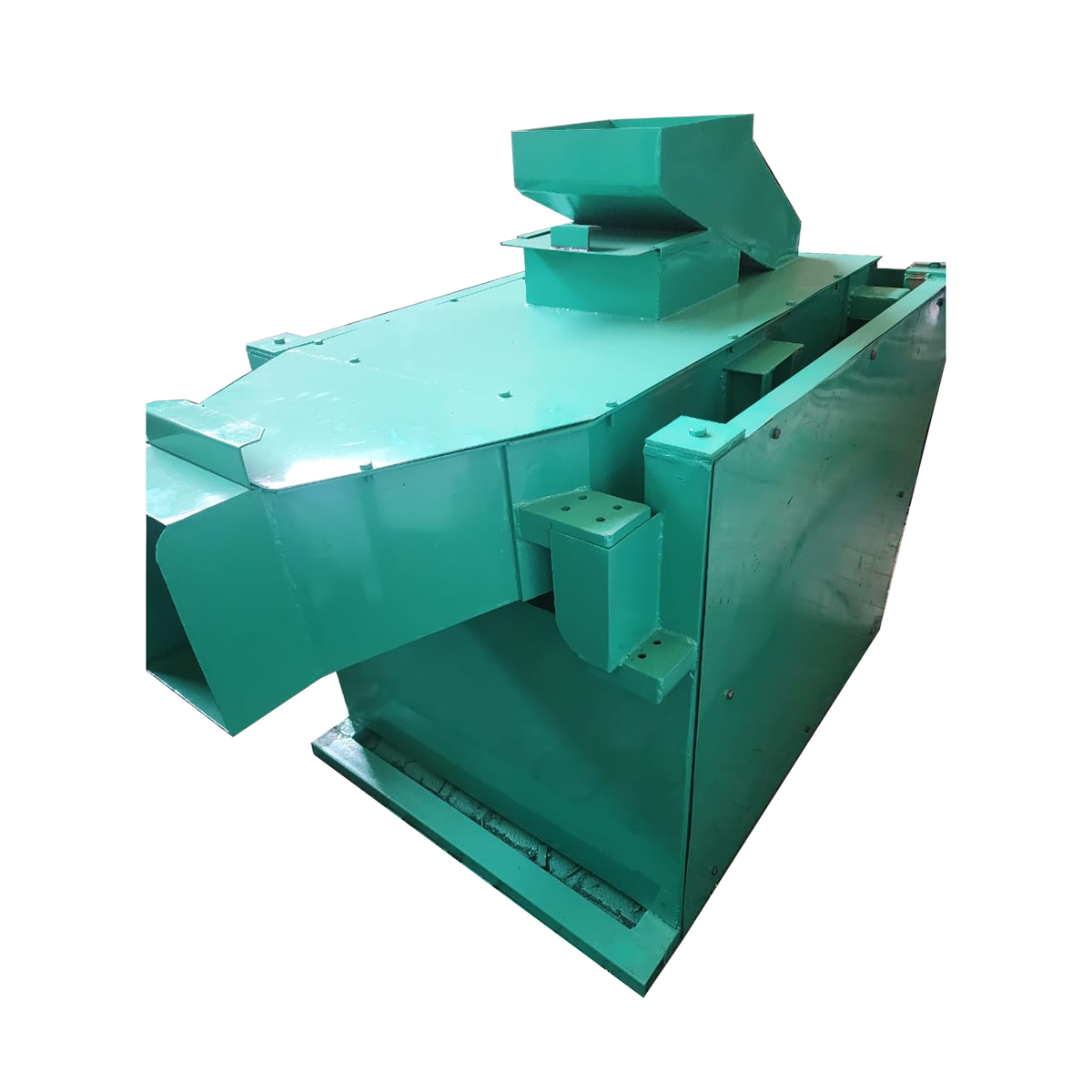

- Hammer Mill / Feed Grinder Machine: Grinds raw materials into fine mash. Smaller screen sizes are used to achieve the particle size required for poultry feed.

Step 3: Mixing & Nutrient Dosing

This stage ensures accurate and consistent nutrition in every batch.

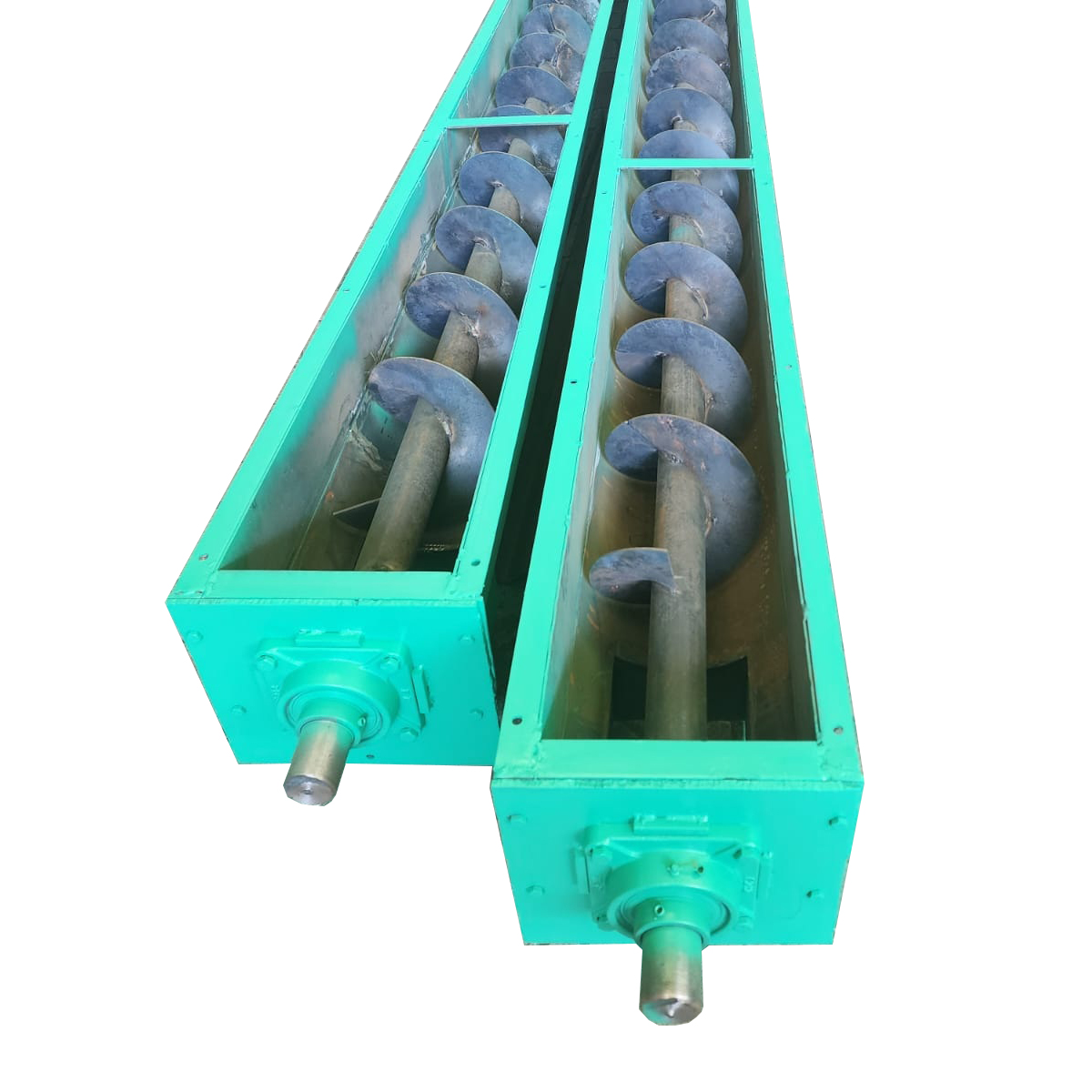

- Screw Conveyor: Transfers the ground mash from the hammer mill to the mixer in an enclosed system, minimizing dust and feed loss.

- Feed Mixture Machine: Vitamins, minerals, amino acids, and supplements are added and thoroughly mixed to produce a homogeneous poultry feed blend.

Step 4: Pelleting Process

The mixed mash is converted into poultry feed pellets.

- Feed Pellet Mill: The feed mash is compressed through a precision die to produce small-diameter, high-density poultry feed pellets, suitable for broilers and layers.

Step 5: Cooling & Crumbling

Pellets are stabilized and sized according to bird age.

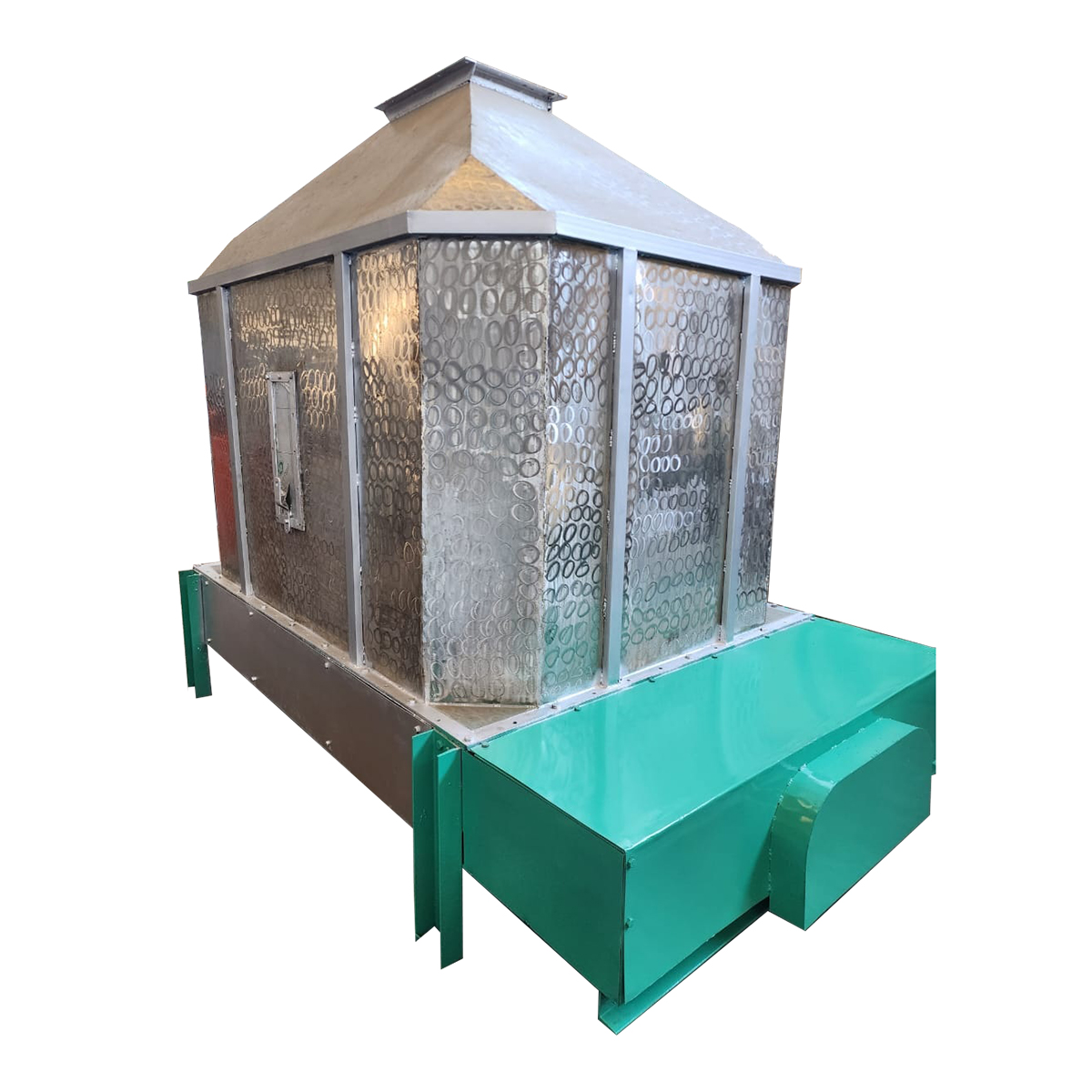

- Cattle Feed CF Cooler: Uses ambient air to cool pellets, reduce moisture, and increase pellet hardness and shelf life.

- Feed Crumbler Machine: (For chicks) Pellets are passed through the crumbler to produce uniform crumbles suitable for young birds.

Step 6: Final Conveying & Packing

Finished poultry feed is transferred to storage or packing.

- Chain Conveyor: Gently conveys cooled pellets or crumbles to packing units, reducing breakage and dust formation.

Final Output

- Uniform, nutritionally balanced poultry feed

- Improved feed conversion ratio (FCR)

- Strong pellets with minimal fines

- Efficient, continuous production